- HOME

- Technology and Production System

- Production and Quality System

Production and Quality System

Die production and quality control systems unrivaled in the industry

NICHIDAI uses die-production equipment unrivaled in the industry to manufacture a wide variety of thousand of dies each month that satisfy its customers. This is supported by the precision process technology of a micron order the company has developed for a long time, the company’s production control system that combines optimum processes matching product specifications, the daily actions by its production team in view of “own-process completion”, and its reliable quality control system.

Advantages of NICHIDAI’s die production

- NICHIDAI provides high-precision and high-quality processing of dies that meets its customers’ requirements through its internal designing process based on their needs its sales force grasps. The company also has built its quality assurance system that obliges the inspection of all items.

- NICHIDAI achieves quality assurance, the improvement of lead time, and cost reduction by owning the equipment required for die-making and building a full-scale manufacturing system.

- NICHIDAI develops optimum production plans that meet its customers’ requirements changing daily. It also centrally controls its manufacturing process using a bar-code control system on individual dies to boost awareness of delivery date.

Manufacturing process

Heat treatment

NICHIDAI has achieved automation and built its quality control system using FMS (Flexible Manufacturing System) prior to its competitors in the industry since 1988

Assembly

NICHIDAI internally prepares shrink fitting that is key to the improvement of service life of cold forging dies.

Electric discharge machining

NICHIDAI owns more than 20 electric discharge machines to achieve the precision processing of hard metals such as cemented carbide.

The company has in-house manufactured electrodes (copper, copper-tungsten, graphite) to use for electric discharge machining and achieved high-precision processing.

Wire discharge is also used depending on the shape of material to address a variety of applications.

Machining

NICHIDAI provides high-precision processing with direct-carving of hard material (equivalent to HRC70). It also has five-axis machines to address processing of products with complicated geometries.

Precision grinding

Products with special geometries such as gear are processed to ultra-high precision (JISO class).

Lapping

Using its self-development tool (commonly known as “lathe”), NICHIDAI’s experienced engineers achieve surface roughness of Rz0.4 or less by mirror-like finishing.

Surface treatment

NICHIDAI owns PVD coating equipment internally to meet its customers’ requirements.

Inspection

All items in all sites are inspected in the process each product is finished with individual specifications. NICHIDAI uses seven 3D measuring devices of ZEISS to address the processing that is difficult for human beings to make decisions on.

Quality assurance

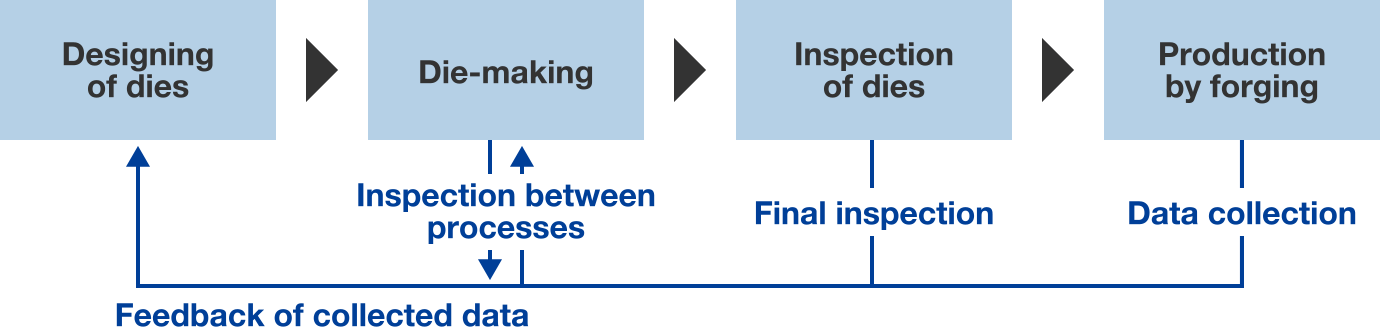

Working on TQM (Total Quality Management), NICHIDAI performs strict inspections and evaluations in all processes including the designing of dies, production processes, and inspections. All data collected in those processes are evaluated for their relations to molded articles and fed back to each process to improve customer satisfactions.

NICHIDAI QC System

Mission of NICHIDAI’s Overseas Factory

In 2013, NICHIDAI (Thailand) Ltd. started its production of dies and has been working on its production activities that meet the requirements of its customers in Thailand and other Asian regions. In production activities in Thailand, standardization is implemented more widely than in Japan to entrench the heart and essence of NICHIDAI’s die-making there.

Production system in NICHIDAI (THAILAND) LTD.

To realize production with Japanese quality level in Thailand, NICHIDAI accepts in rotation its Thai staff members to its factory in Japan and gives them trainings. The company focuses on the education of local staff members involved in lapping that is a particularly important factor for die-making, which is receiving favorable evaluations from its customers.

Production in Thai factory

Training in Ujitawara factory