- HOME

- Products and Contracted Development

- Precision Forgings

Precision Forgings

Mass Production of Precision Forgings Using Proprietary Technology and Company-owned Equipment

NICHIDAI mass-produces precision forgings taking advantage of technologies related to forging it has developed for many years. The company solves a variety of its customers’ problems such as small lots difficult to handle, conversion from the conventional method to forging, and special products that they cannot handle internally.

Advantages as a “professional company for dies”

- Sound forging technologies to enable self-development and the proposal ability endorsed by them

- Technology of dies that is key to forgings as well as readiness for customers

- Active implementation of new technologies such as one-component lubrication

- Production and quality control systems applicable to mass production (the relevant certifications received)

Company-owned presses

NFD-1000

L1C-400L

L2C-1250L

FMX-1000

Forging and forming technologies for aluminum alloy

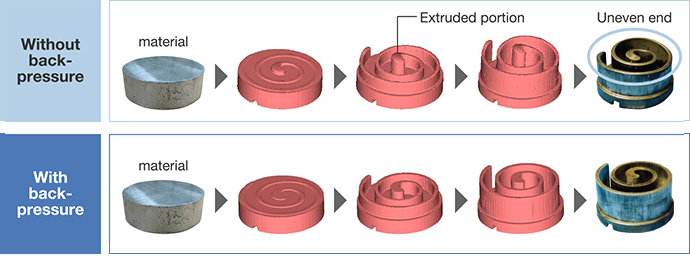

NICHIDAI also actively works on the precision forging of non-ferrous metals. Particularly, the company not only provides dies and die sets together with its technologies for high-silicon aluminum alloy scrolled parts it has successfully developed to be its proprietary precision forging process, but also mass produces those parts using its own full-scale automatic production line. The forging process using its patented “back pressure mechanism” brings advantages such as leveled height of laps. This technology is also applied to a variety of other forgings with laps.

Advantages of NICHIDAI’s aluminum alloy scrolled parts

- High-precision die-making technology from in-house manufacturing

- Pioneering forming technology (back-pressure control, lubrication control, temperature control)

Advantages of using back-pressure mechanism

Without back-pressure: The uneven end of the scroll causes a higher cutting cost and a lower yield.

With back-pressure: The even end of the scroll keeps the cutting cost low.

Deformation process in extrusion forging

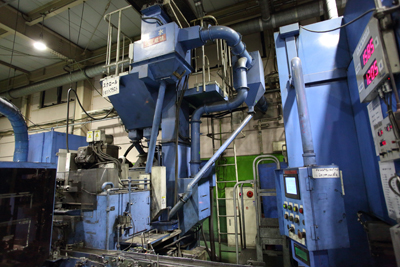

Production line for scrolls

NICHIDAI has dedicated production lines for scrolls to address their mass production and the continuous improvement of its technological ability. It also has built the same line in the factory of NICHIDAI (THAILAND) LTD. to establish the bipolar production system by Japan and Thailand.

Press

Press

Heat treatment

Heat treatment

Shot blast

Shot blast

Automatic inspection

Automatic inspection