- HOME

- Products and Contracted Development

- Forging DX

Forging DX

Visualize dies damage and product defects, aiming for a production system that does not produce defects

1. Detecting deterioration of the dies

Traditionally, abnormalities in the dies were determined through visual inspection of the product by skilled workers. However, by visualizing the condition of the dies with sensors, changes such as damage or wear can be detected in real-time based on data, enabling optimal management of the dies.

2. Prediction of dies lifespan

Visualizing the condition of the dies enables the analysis of collected data to capture phenomena that were previously undetectable, enabling the prediction of its lifespan. Furthermore, we aim to provide our customers with even more valuable services, such as extending the lifespan through maintenance or suggesting replacement timing, based on this information.

3. Evaluating the quality of forged products without inspection

Traditional quality evaluation required on-site evaluation of the physical product. However, by clarifying the relationship between data collected during production and product quality, we aim to establish a system that can guarantee quality without directly evaluating the product.

Received the BEST Award of IVI Connected Manufacturing Award 2022

Regarding our development of Forging DX, we have received the Best Award of IVI*1 Connected Manufacturing Award 2022.

Industrial Value Chain Initiative

- *1:

- IVI stands for "Industrial Value Chain Initiative" which is a consortium established to aim for the digital transformation of manufacturing by integrating manufacturing and IT technologies.

Nichidai will achieve Forging DX through the following two technologies

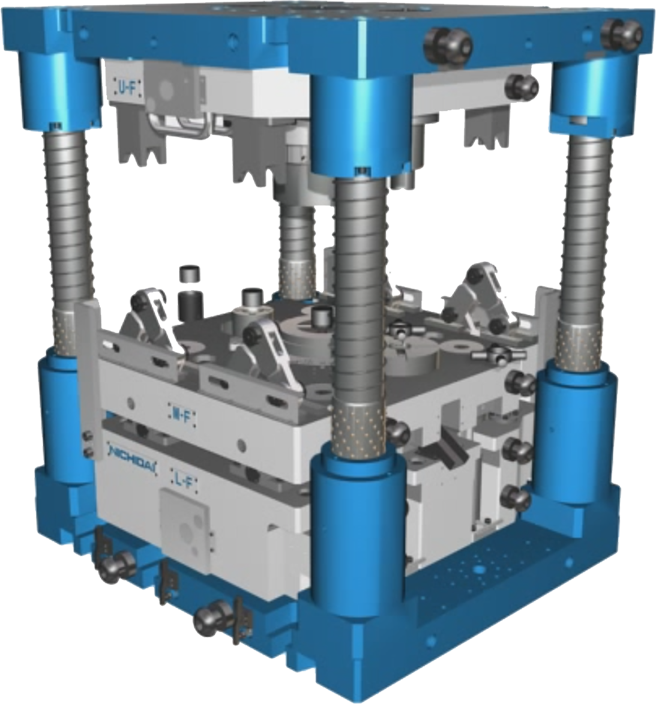

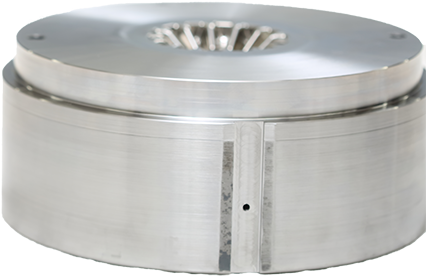

Intelligent die set

We will incorporate various sensors for visualizing the condition of the dies into the die set

Visualizing

the inside of

a press as data

Sensors mainly incorporated into the die set

-

Load sensor

Measure the actual load for each dies during diesing

-

Displacement sensor

Measure the distance between diess during diesing

-

Temperature sensor

Measure the temperature changes of the dies during diesing

-

Acoustic emission sensor

Detect changes in the dies and peripheral equipment through vibration using an acoustic emission sensor

Vibration (acceleration) sensor

Detect smaller changes in the dies and peripheral equipment through vibration using a vibration (acceleration) sensor

-

Network camera

Record the status in conjunction with diesing

Customization of various sensors is available according to the customer's needs. By installing the Intelligent die set, it is possible to collect production data with existing equipment (press machines).

Manufacturing management system

We aim to achieve quantitative quality management by collecting, visualizing, and analyzing data during mass production

By combining multiple sensors such as AE, load, and displacement sensors, we can detect abnormalities in diess at a much earlier stage than conventional methods, aiming to prevent product defects and other issues.

Aiming to achieve a production system that does not produce defective products

We may not notice abnormalities in molds even if we monitor them on-site. However, continuing to press with a mold that has abnormalities will result in producing a large quantity of defective products. To solve this challenge through Forging DX, this product has been developed. A major feature is that it can be used with the conventional press machine by only replacing the die set. Nichidai is committed to tackling the long-standing challenge in the mold industry of not producing defective products with all our efforts.