- HOME

- Technology and Production System

- Technology and Development System

Technology and Development System

NICHIDAI will propose optimum forging technologies with its proprietary systems for development support.

The total engineering system of NICHIDAI is supported by its high-level technological development ability. Having more than 30 technical engineers, NICHIDAI helps its customers realize what they want by using forging die technologies it developed and cutting-edge ICTs. The company also has test presses applied together with its die-making technology to meet a variety of development needs.

Technology development department

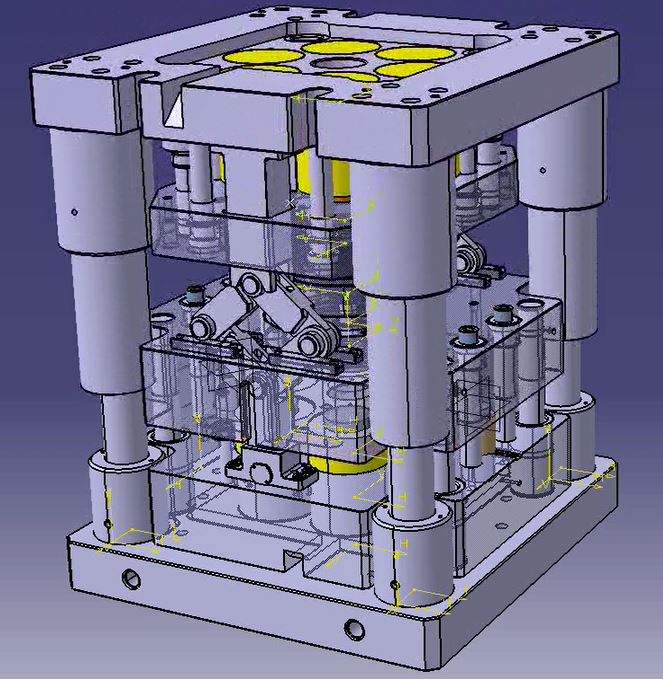

CAD system screen

Die-designing Technology

Process designing

NICHIDAI will propose optimum processes to its customers that meet their product specifications and all processes from the proposal of materials to final products.

Die-designing

NICHIDAI provides a comprehensive support to the designs of peripheral equipment and appliances such as die-set as well as of dies using its designing know-how it has developed for a long time and meeting the specifications of its customers’ equipment.

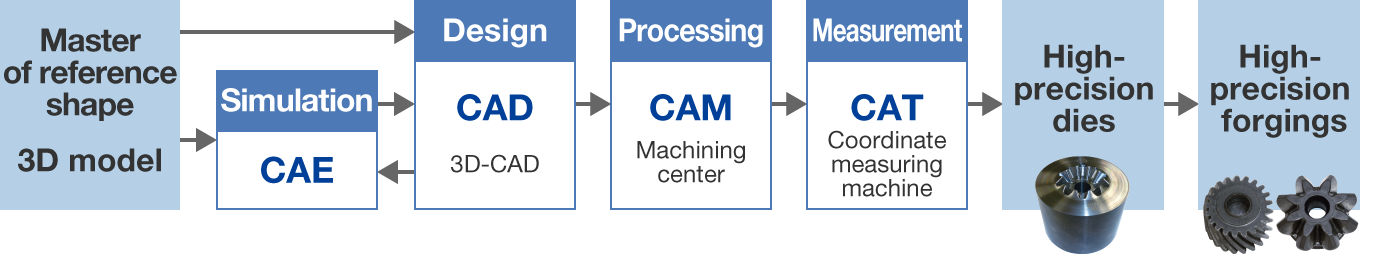

CAD/CAE/CAM/CAT

NICHIDAI has adopted ICTs from early on and now uses CAD/CAE/CAM/CAT tools to address customers’ requirements for analysis.

Overview of CAE

CAE technology is applied to designing of forging processes and dies (covering 2D and 3D) as well as contracted and internal developments.

※3D CAD : CATIA V5、NX、SPACE-E CAE : simufact.forming

※3D CAD : CATIA V5、NX、SPACE-E CAE : simufact.forming

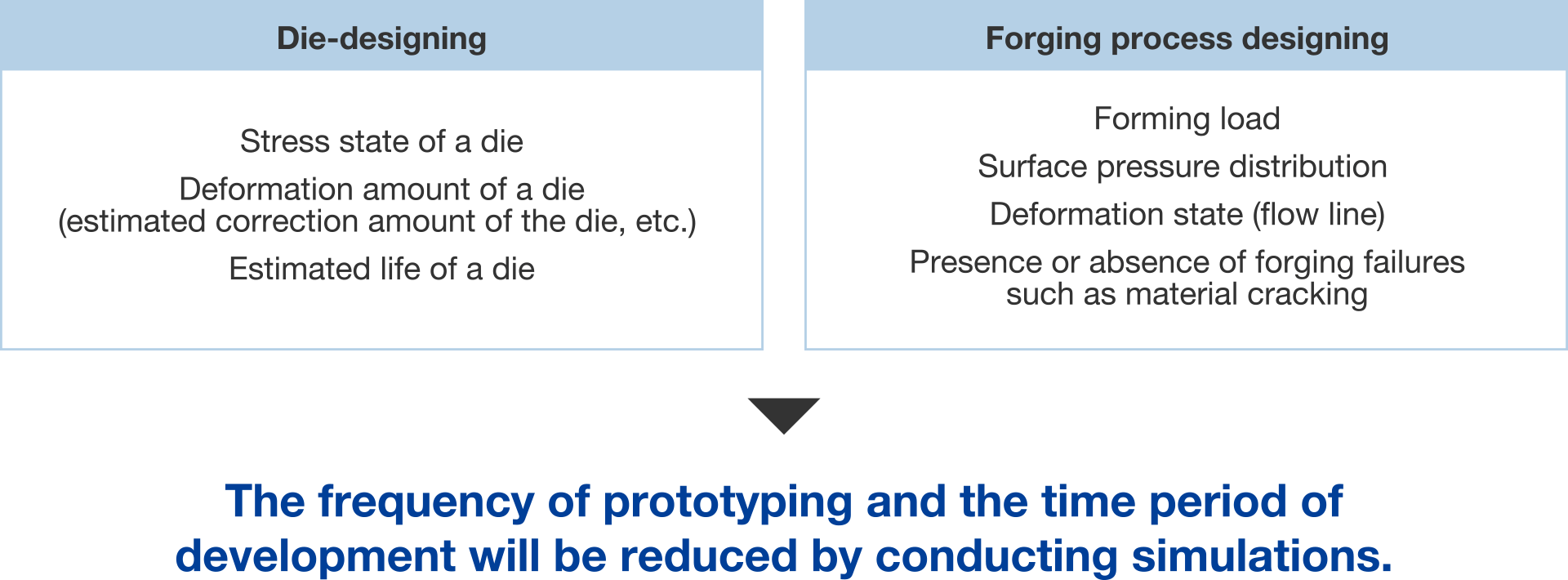

What is checked using CAE

Advantage of CAE

Applied to designing of forging processes and dies (covering 2D and 3D) as well as contracted and internal developments.

Analysis cases

Enclosed forging

Deformation state, forming load required for forming, and enclosing load are checked.

Self-development cases

NICHIDAI undertakes contracted development projects from customers and works on collaborative development with them as well as on self-development.

High-precision forming technology that controls the elastic deformation of die

This technology improves the accuracy of out-of-roundness by preventing burrs from being generated on the axis of a cross joint and controlling the elastic deformation of a die occurring at the time of forming.

[Comparison with conventional technologies]

![Comparison with conventional technologies]](/english/img/tec_system_img5.png)

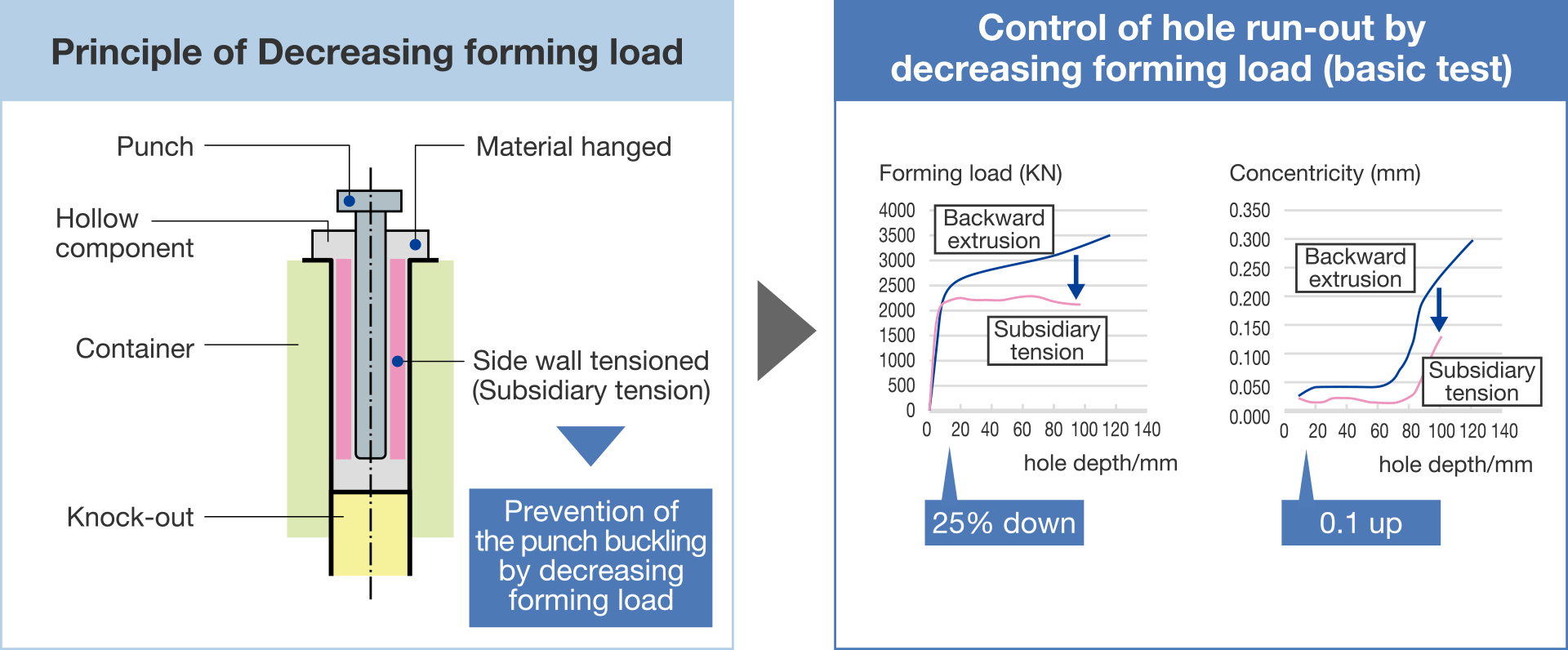

Forming method for hollow components Technique to decrease forming load with subsidiary tension

Forming load can be decreased in comparison with conventional method by applying subsidiary tension. Thereby, the punch buckling can be prevented.

[Decrease of forming load with subsidiary tension.]

List of main basic tests

NICHIDAI is working on basic researches in a variety of fields related to die and forging for the improvement of its elemental technology and the development of new technologies.

| Name of tester | Year of implementation | Implementation matters |

|---|---|---|

| Material tester | 1994 | Tension / Compression test (50 t) |

| 3D digitizer | 2011 | Geometry measurement in a development test |

| 3D printer | 2011 | Forming of prototype and simple jig |

| Micro Vickers hardness meter | 2015 | Measures the hardness of die and forging |

| X-ray residual stress measuring device | 2017 | Measures the residual stress on die and forging Measurement of residual austenite |

| High temperature tension compression type fatigue tester | 2017 | Fatigue test in high and room temperatures (5 t) Tension / Compression test (6 t) |

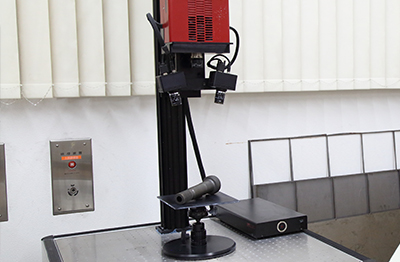

3D digitizer

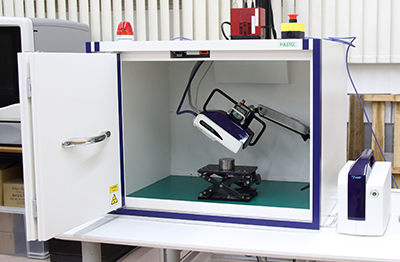

X-ray residual stress measuring device

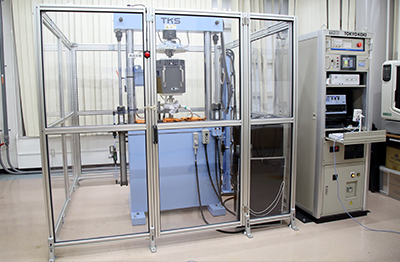

High temperature tension compression type fatigue tester

R & D Report

We will introduce a research report on forging technology at NICHIDAI.

| Subject | Name | Journal title | Posted Year |

|---|---|---|---|

| DIE TECHNOLOGY FOR PRECISION FORGING | Eisuke Murai | The 8th JSTP International Seminar on Precision Forging Organaized by the Japan Society for Technology of Plasticity | March 5-8, 2018 |

| DEVELOPMENT OF DOUBLE CUP FORMING IN PLATE FORGING | Kazuya Takeshita | The 8th JSTP International Seminar on Precision Forging Organaized by the Japan Society for Technology of Plasticity | March 5-8, 2018 |